Copper strip manufacturing in India has evolved significantly over the years, becoming a crucial part of the country’s industrial landscape. As a versatile material, copper strips are used in various applications ranging from electrical components to architectural projects. The manufacturing process involves precision and expertise to ensure high-quality products that meet industry standards.

India is home to numerous copper strip manufacturers, each playing a pivotal role in supplying both domestic and international markets. The country’s favorable economic policies and availability of raw materials have fostered growth in this sector. Additionally, the increasing demand for electrical and electronic products has further propelled the need for reliable copper strip manufacturers in India.

The strategic location of these manufacturers facilitates easy access to ports and logistic networks, enabling swift distribution. This accessibility, coupled with the skilled workforce, makes India a prominent player in the global copper strip manufacturing industry.

Importance of Quality in Copper Strips

Quality is paramount when it comes to copper strips, as it directly impacts the functionality and longevity of the end product. High-quality copper strips ensure efficient conductivity, resistance to corrosion, and durability, which are essential for applications in the electrical and electronic industries. Poor-quality copper strips can lead to significant losses and inefficiencies in the production process.

Manufacturers invest heavily in quality control processes to maintain the integrity of their copper strips. This includes rigorous testing for tensile strength, electrical conductivity, and dimensional accuracy. By adhering to strict quality standards, manufacturers can guarantee that their products meet the specific requirements of various industries.

Furthermore, the reputation of copper strip manufacturers in India hinges on their ability to consistently deliver quality products. A strong commitment to quality not only enhances customer satisfaction but also builds trust and long-term relationships. Therefore, choosing a manufacturer that prioritizes quality is crucial for businesses relying on copper strips.

Leading Copper Strip Manufacturers in India

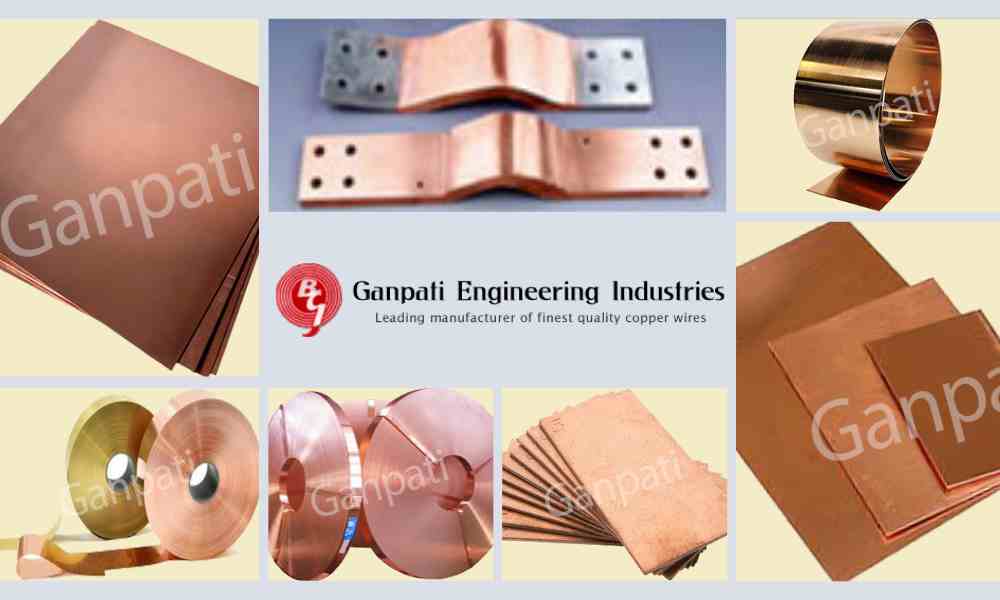

One of the renowned names in the copper strip manufacturing industry is Ganpati Engineering Industries, also recognized as a leading copper wire manufacturer in India. Known for its commitment to quality and innovation, Ganpati Engineering Industries stands out as a leader among copper strip manufacturers in India. The company specializes in producing high-grade copper strips that cater to a wide range of industrial needs.

Ganpati Engineering Industries offers a diverse portfolio of copper products, including flat copper strips, round copper wires, and custom solutions tailored to specific requirements. Their state-of-the-art manufacturing facilities and experienced workforce ensure that every product meets stringent quality standards.

In addition, Ganpati Engineering Industries places a strong emphasis on customer satisfaction. By offering excellent after-sales support and maintaining open communication channels, they establish trust and reliability with their clients. Choosing a manufacturer like Ganpati Engineering Industries guarantees access to top-notch copper strips backed by decades of expertise.

Factors to Consider When Choosing a Manufacturer

Selecting the right copper strip manufacturer is a critical decision that can significantly impact your business operations. Several factors should be taken into account to ensure you partner with a reliable and capable manufacturer. Here are some key considerations:

Quality Assurance:

Verify that the manufacturer follows stringent quality control measures and holds relevant certifications. This ensures the copper strips meet industry standards.

Experience and Reputation:

Research the manufacturer’s history and reputation in the industry. A company with extensive experience and a solid track record is likely to deliver dependable products.

Customization Capabilities:

Depending on your specific needs, you may require custom copper strips. Ensure the manufacturer can produce tailor-made solutions.

Cost and Delivery:

Compare pricing and delivery timelines among different manufacturers. Opt for a company that offers competitive pricing without compromising on quality or delivery speed.

Customer Support:

Choose a manufacturer that provides excellent customer service and support. Effective communication and problem-solving capabilities are essential for a successful partnership.

By thoroughly evaluating these factors, you can make an informed decision and select a manufacturer that aligns with your business goals and requirements.

Industry Standards and Certifications for Copper Strips

Adhering to industry standards and certifications is vital for copper strip manufacturers in India. These standards ensure that the products are safe, reliable, and suitable for their intended applications. Several key standards and certifications are prevalent in the copper strip manufacturing industry:

- ISO 9001 Certification: This international standard specifies requirements for a quality management system, ensuring that manufacturers consistently provide products that meet customer and regulatory requirements.

- ASTM Standards: The American Society for Testing and Materials (ASTM) develops and publishes technical standards for a wide range of materials, including copper. Compliance with ASTM standards ensures the quality and performance of copper strips.

- RoHS Compliance: The Restriction of Hazardous Substances (RoHS) directive restricts the use of certain hazardous materials in electrical and electronic equipment. RoHS compliance is crucial for manufacturers exporting to European markets.

- BIS Certification: The Bureau of Indian Standards (BIS) certification indicates conformity with Indian standards, ensuring product safety and quality for the domestic market.

Manufacturers that adhere to these standards demonstrate a commitment to quality and safety, enhancing their credibility and competitiveness in the industry.

Applications of Copper Strips in Various Industries

Copper strips are indispensable in various industries due to their excellent electrical conductivity, thermal properties, and malleability. Here are some common applications:

Electrical and Electronics:

Copper strips are widely used in electrical wiring, transformers, and circuit boards. Their superior conductivity makes them ideal for efficient power transmission.

Automotive:

In the automotive industry, copper strips are used in wiring harnesses, electric vehicle components, and battery connectors, contributing to vehicle performance and safety.

Construction and Architecture:

Copper strips are used in roofing, cladding, and plumbing due to their corrosion resistance and aesthetic appeal. They also find applications in HVAC systems.

Telecommunications:

Copper strips are essential in telecommunications for manufacturing cables and connectors, ensuring reliable signal transmission.

Industrial Machinery:

In industrial machinery, copper strips are used in motors, generators, and heat exchangers, where they enhance energy efficiency and durability.

The versatility of copper strips makes them a critical component in numerous sectors, driving the demand for high-quality products from reputable manufacturers.

Future Trends in the Copper Strip Manufacturing Industry

The copper strip manufacturing industry is poised for growth, driven by technological advancements and increasing demand across various sectors. Here are some future trends to watch:

- Sustainable Practices: With growing environmental awareness, manufacturers are adopting sustainable practices, such as recycling and energy-efficient production methods, to reduce their carbon footprint.

- Innovation in Alloys: Research and development efforts are focused on creating new copper alloys that offer enhanced properties, such as improved strength and conductivity, to meet evolving industry needs.

- Digitalization and Automation: The integration of digital technologies and automation in manufacturing processes is enhancing efficiency, accuracy, and productivity, leading to cost-effective production.

- Expansion in Emerging Markets: As emerging markets continue to develop, the demand for copper strips is expected to rise, presenting new opportunities for manufacturers to expand their reach.

By embracing these trends, copper strip manufacturers in India can stay competitive and meet the growing demands of a dynamic global market.

Conclusion

In conclusion, the copper strip manufacturing industry in India is a dynamic and essential part of the country’s industrial fabric. With a focus on quality, innovation, and sustainability, manufacturers like Ganpati Engineering Industries lead the way in providing top-notch copper strips for various applications. By considering factors such as quality assurance, experience, and certifications, businesses can make informed decisions when selecting a manufacturer.

As the industry continues to evolve, staying abreast of future trends and maintaining a commitment to excellence will be key to success. Whether you are in the electrical, automotive, or construction sector, partnering with a reliable copper strip manufacturer is crucial for achieving your business objectives.

If you’re looking for a trusted supplier of high-quality copper strips, consider reaching out to us for more information and expert guidance. Our team is dedicated to meeting your specific needs and ensuring the success of your projects. Contact us today to learn more about our products and services.