Submersible Copper Winding Wire

Buy Pure Quality Submersible Copper Winding Wire Online!

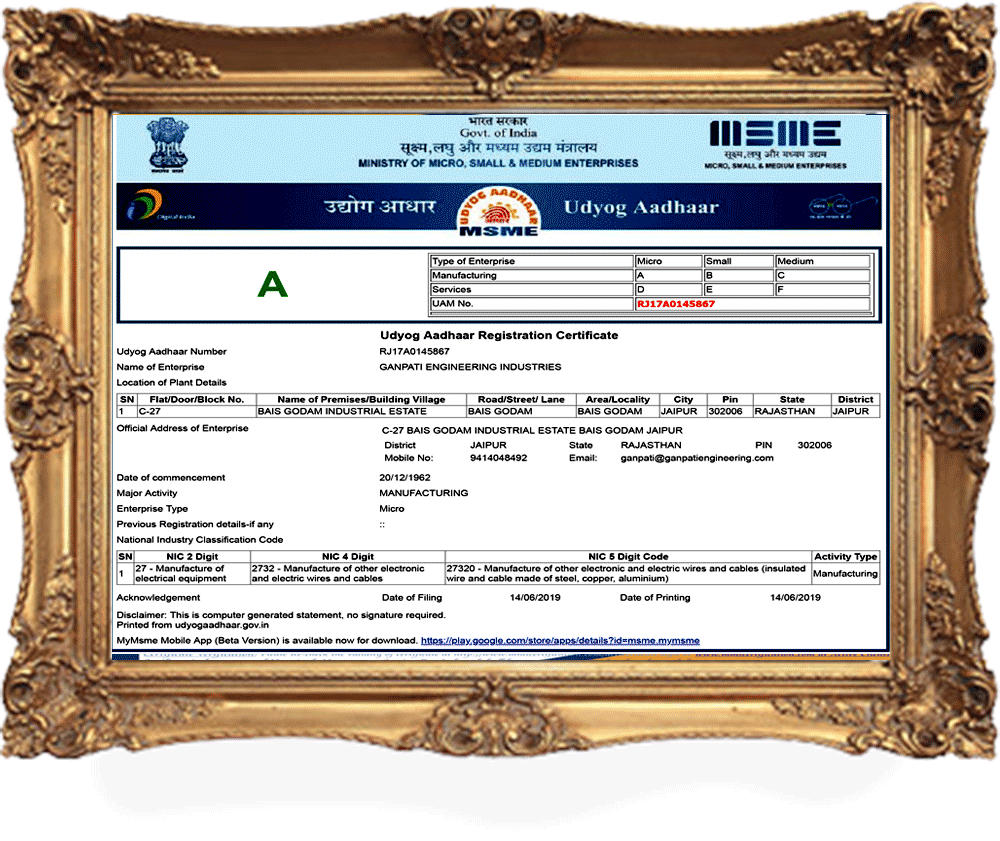

The winding wires are the backbone of submersible copper winding wire industry due to its vital role in any process related to this domain. So crucial the use of these wires are, that even a slightest fault in their quality can cause a complete and even permanent failure (in some cases) of the highly expensive equipments. Understanding this fact very well, our Ganpati Engineering Industries gives a considerable focus to the quality Manufacturing of the winding wires delivered in the market for sale. Before reaching in the market, our products are rigorously tried and tested to ensure their supreme quality and high reliability. The specifications of these products are as per the industry standard and even better than specified in the IS specifications in some cases.

The equipments of copper are made of pure electrolytic grade of copper to ensure that our customers get complete value for their money. Due to their sublime quality, our Submersible copper winding wires are not only comparatively highly reliable but also save the consumption of power, to further benefit the end users. To provide these conductors with extra softness, the complete range is annealed as per our high standards. The properties (including chemical, thermal, mechanical and electrical) of these products are completely intact with the details specified as per IS.

Item Code : SWW-005

The Conductors are drawn and annealed as per the specification. These conductors are insulated with polyester film and polypropylene tape, which have higher insulation resistance even at boiling point of water. Multiple layers of insulation tape are wrapped around the conductor, which ensure high dielectric quality of insulation of the winding wire. The structure of insulation is oriented biaxial, to provide tear resistance and flexibility. The surface of the finished winding wire is reasonably smooth and natural in color.

Features:

- Resistance to abrasion

- Low power consumption

- Tear resistance

- Outstanding electrical, mechanical properties

- Economical

Higher Life : Â Submersible Copper Winding Wire have excellent, Electrical, Mechanical, Thermal & Chemical properties. These wires withstand abrasion, frictional losses and work in every type of typical conditions. The insulating material is produced by biaxially oriented synthetic film and places the insulation concentrically around the conductor and has very high life.

Item Code : SWW-006

The Conductors are drawn and annealed as per the specification. These conductors are insulated with polyester film and polypropylene tape, which have higher insulation resistance even at boiling point of water. Multiple layers of insulation tape are wrapped around the conductor, which ensure high dielectric quality of insulation of the winding wire. The structure of insulation is oriented biaxial, to provide tear resistance and flexibility. The surface of the finished winding wire is reasonably smooth and natural in color.

Features:

- Resistance to abrasion

- Low power consumption

- Tear resistance

- Outstanding electrical, mechanical properties

- Economical

Higher Life : Â Submersible Copper Winding Wire have excellent, Electrical, Mechanical, Thermal & Chemical properties. These wires withstand abrasion, frictional losses and work in every type of typical conditions. The insulating material is produced by biaxially oriented synthetic film and places the insulation concentrically around the conductor and has very high life.

Item Code : SWW-007

The Conductors are drawn and annealed as per the specification. These conductors are insulated with polyester film and polypropylene tape, which have higher insulation resistance even at boiling point of water. Multiple layers of insulation tape are wrapped around the conductor, which ensure high dielectric quality of insulation of the winding wire. The structure of insulation is oriented biaxial, to provide tear resistance and flexibility. The surface of the finished winding wire is reasonably smooth and natural in color.

Features:

- Resistance to abrasion

- Low power consumption

- Tear resistance

- Outstanding electrical, mechanical properties

- Economical

Higher Life : Â Submersible Copper Winding Wire have excellent, Electrical, Mechanical, Thermal & Chemical properties. These wires withstand abrasion, frictional losses and work in every type of typical conditions. The insulating material is produced by biaxially oriented synthetic film and places the insulation concentrically around the conductor and has very high life.

Item Code : SWW-008

The Conductors are drawn and annealed as per the specification. These conductors are insulated with polyester film and polypropylene tape, which have higher insulation resistance even at boiling point of water. Multiple layers of insulation tape are wrapped around the conductor, which ensure high dielectric quality of insulation of the winding wire. The structure of insulation is oriented biaxial, to provide tear resistance and flexibility. The surface of the finished winding wire is reasonably smooth and natural in color.

Features:

- Resistance to abrasion

- Low power consumption

- Tear resistance

- Outstanding electrical, mechanical properties

- Economical

Higher Life : Â Submersible Copper Winding Wire have excellent, Electrical, Mechanical, Thermal & Chemical properties. These wires withstand abrasion, frictional losses and work in every type of typical conditions. The insulating material is produced by biaxially oriented synthetic film and places the insulation concentrically around the conductor and has very high life.

Submersible Copper Winding Wire

Our conductors are rigorously tested and their test results beat the industry specified standards in almost all cases. The tests we perform include spring back test, conductor resistance test and elongation test. If the grade of films of poly and propylene is inferior, there will always remain a possibility of pump failure. This is why we always use supreme quality of layers which deliver high insulation resistance even at 100 degree centigrade. The strength of these layers and tapes has been maintained as per the size of the conductor.

Thanks to our world class facility, we use the latest technology in Manufacturing and layering. This facility also enables us to conduct a variety of tests on manufactured goods including the likes of water absorption test, insulation test, spark test, hot deformation test, shrinkage test, high voltage test, spark test, etc. Even the packaging of these products has been given a high importance as it plays an important role in quality control. The proper packaging safeguards these wires from sharp edges which otherwise can prove very harmful and dangerous for the complete set-up if used anywhere in the industry.