Stranded Tin Coated Copper Wire

Finest Quality Stranded Tin Coated Copper Wire at Lowest Price Ever!

Most of you must of aware that the use of copper wires is highly imperative due to its amazingly high conductivity. However, very few of you may not know that tin coating can enhance durability of copper wires significantly. This is the reason why tin coated copper wires are used in the industries where these are exposed to certain type chemical guesses that can have a high corroding effect. The tin coating works as a safeguard against any sort of corroding effect.

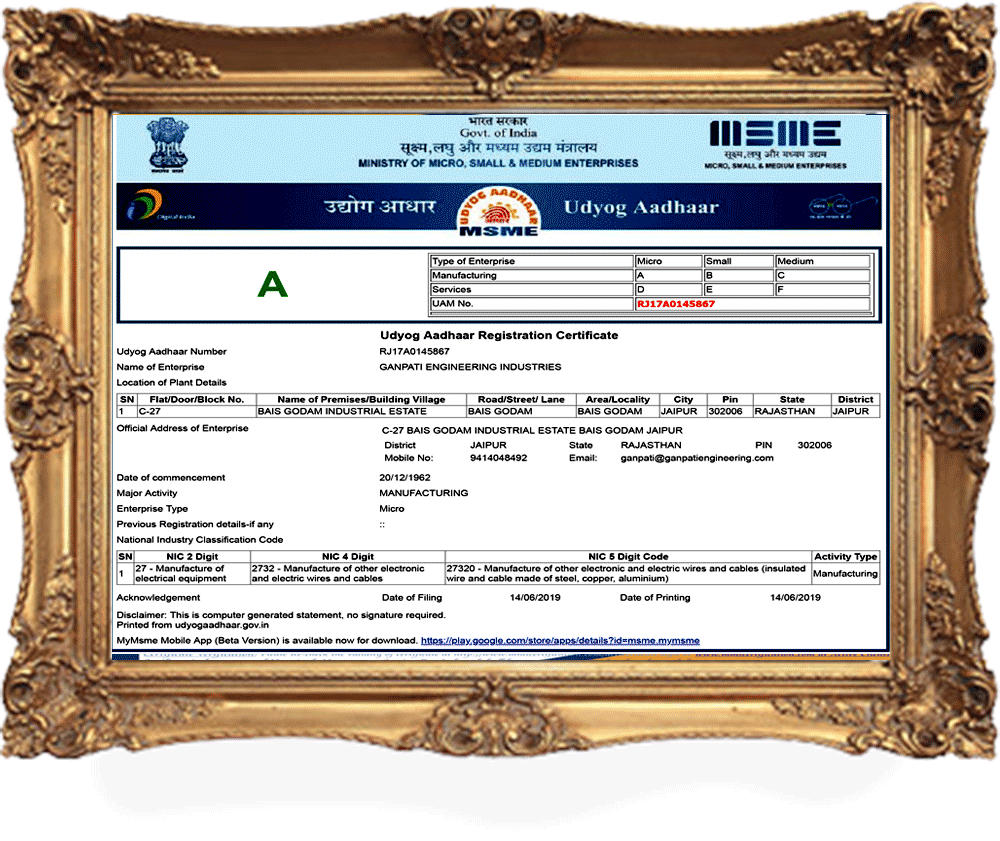

Moreover, the conductivity of the copper wire can be further improved with tin coating at places where complex size stranded tin coated copper wires are used. Having an expertise in the Manufacturing of tin coated wiring solutions, Ganpati Engineering Industries has been offering variety of products in this category for a long time now. Our products have been appreciated by the industry experts for their sublime quality and finish.

The process of Manufacturing copper wires with tin coating is strictly followed at our facility, and this is why most of our products exceed customer expectations most of the times. The quality testing results of our tin coated wires exceed the desired standards, ensuring high reliability and durability. Generally, there are two processes through which the tin coated copper wires can be produced. The first one is called the Hot – Dip process, in which the melted tin is incorporated on the stranded tin coated copper wire by dipping the wire in the electric pot. The second process is called the electroplating process in which electroplating process is initiated by making the wire through a chemical tray.

Item Code : TC-CW-009

Tin is a chemical element with symbol Sn (for Latin: stannum) and atomic number 50. It is a main group metal in group 14 of the periodic table. Tin shows chemical similarity to both neighboring group-14 elements, germanium and lead and has two possible oxidation states, +2 and the slightly more stable +4. Tin is the 49th most abundant element and has, with 10 stable isotopes, the largest number of stable isotopes in the periodic table. Tin is obtained chiefly from the mineral cassiterite, where it occurs as tin dioxide, SnO2.

This silvery, malleable post-transition metal is not easily oxidized in air and is used to coat other metals to prevent corrosion. The first alloy, used in large scale since 3000 BC, was bronze, an alloy of tin and copper. After 600 BC pure metallic tin was produced. Pewter, which is an alloy of 85–90% tin with the remainder commonly consisting of copper, antimony and lead, was used for flatware from the Bronze Age until the 20th century. In modern times tin is used in many alloys, most notably tin/lead soft solders, typically containing 60% or more of tin.

Item Code : TC-CW-010

Tin is a chemical element with symbol Sn (for Latin: stannum) and atomic number 50. It is a main group metal in group 14 of the periodic table. Tin shows chemical similarity to both neighboring group-14 elements, germanium and lead and has two possible oxidation states, +2 and the slightly more stable +4. Tin is the 49th most abundant element and has, with 10 stable isotopes, the largest number of stable isotopes in the periodic table. Tin is obtained chiefly from the mineral cassiterite, where it occurs as tin dioxide, SnO2.

This silvery, malleable post-transition metal is not easily oxidized in air and is used to coat other metals to prevent corrosion. The first alloy, used in large scale since 3000 BC, was bronze, an alloy of tin and copper. After 600 BC pure metallic tin was produced. Pewter, which is an alloy of 85–90% tin with the remainder commonly consisting of copper, antimony and lead, was used for flatware from the Bronze Age until the 20th century. In modern times tin is used in many alloys, most notably tin/lead soft solders, typically containing 60% or more of tin.

Item Code : TC-CW-011

Tin is a chemical element with symbol Sn (for Latin: stannum) and atomic number 50. It is a main group metal in group 14 of the periodic table. Tin shows chemical similarity to both neighboring group-14 elements, germanium and lead and has two possible oxidation states, +2 and the slightly more stable +4. Tin is the 49th most abundant element and has, with 10 stable isotopes, the largest number of stable isotopes in the periodic table. Tin is obtained chiefly from the mineral cassiterite, where it occurs as tin dioxide, SnO2.

This silvery, malleable post-transition metal is not easily oxidized in air and is used to coat other metals to prevent corrosion. The first alloy, used in large scale since 3000 BC, was bronze, an alloy of tin and copper. After 600 BC pure metallic tin was produced. Pewter, which is an alloy of 85–90% tin with the remainder commonly consisting of copper, antimony and lead, was used for flatware from the Bronze Age until the 20th century. In modern times tin is used in many alloys, most notably tin/lead soft solders, typically containing 60% or more of tin.

Item Code : TC-CW-012

Tin is a chemical element with symbol Sn (for Latin: stannum) and atomic number 50. It is a main group metal in group 14 of the periodic table. Tin shows chemical similarity to both neighboring group-14 elements, germanium and lead and has two possible oxidation states, +2 and the slightly more stable +4. Tin is the 49th most abundant element and has, with 10 stable isotopes, the largest number of stable isotopes in the periodic table. Tin is obtained chiefly from the mineral cassiterite, where it occurs as tin dioxide, SnO2.

This silvery, malleable post-transition metal is not easily oxidized in air and is used to coat other metals to prevent corrosion. The first alloy, used in large scale since 3000 BC, was bronze, an alloy of tin and copper. After 600 BC pure metallic tin was produced. Pewter, which is an alloy of 85–90% tin with the remainder commonly consisting of copper, antimony and lead, was used for flatware from the Bronze Age until the 20th century. In modern times tin is used in many alloys, most notably tin/lead soft solders, typically containing 60% or more of tin.

Stranded Tin Coated Copper Wire

The copper wires coated in tin bear a number of unique features including complex shape and specific use. The industries where these types of wires are commonly used include heavy transit systems, industrial cranes, and heavy powered mining trains. The appliances in which tin coated wires are used include the likes of cable and wire cores and electric appliances.

So if you have been in search of the finest quality copper wires, and still not able to find a place worth buying, visit us today at our user friendly website, where the complete range of our products is listed with complete specifications mentioned. While we supply a large range of wiring products, there always remains a scope of Manufacturing specific products to meet the specific customer needs, thanks to our excellent facility.