Glass Coated Wire

Select Top Quality Glass Coated Wire Online!

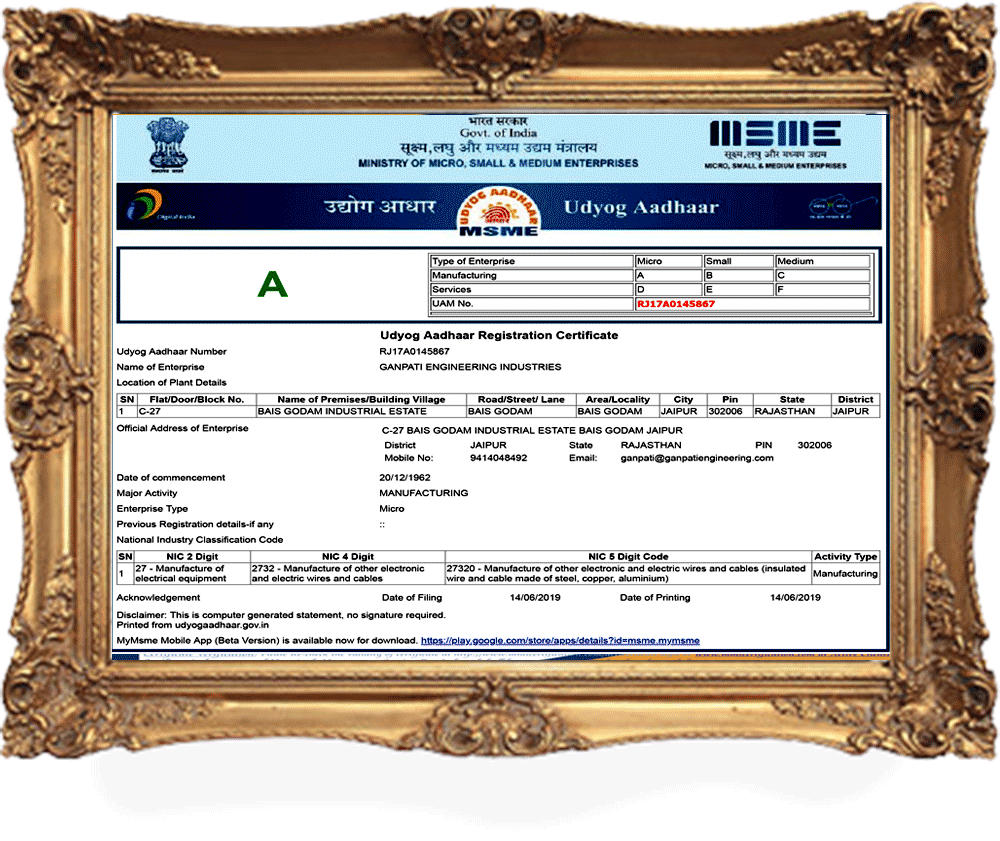

In past few years, the glass coated wire has emerged as one of the most sought after conductors due to their high reliability. These copper wires are drawn from glasses which is the reason why these are called the glass coated wires. The glass coated wire saves the copper wire from atmospheric changes, chemical reactions, insulation and oxidation. The Manufacturing of these types of wires are required to be made with a complete adherence of the process and a very high focus on maintaining quality, because even a slightest fault can prove highly dangerous and even fatal some times. This is why it is imperative to buy them from a trust worthy source like the industry experts Ganpati Engineering Industries. We, at our state of art facility, make sure that the product delivered to you is absolutely fault free.

There are a range of industries where the glass coated wires are used extensively including the likes of aerospace, automotive, bio-medicals, chemicals, electrical industry, high grade electronics device, instrumentations, and oceanographic, military and robotic science. The glass coated wires used in these industries remains fully inorganic in nature along with very smooth and non porous. The glass coated wire not only increases the productivity of the copper wire but also increases its life significantly. Moreover, these types of wires are ideal solutions to the problems like high or low voltage, extreme environment, highly overloading capacity and less availability of space.

Item Code : TCW-005

Glass-coating is a process invented in 1924 by G. F. Taylor and converted into production machine by Ulitovski for producing fine glass-coated metal filaments only a few micrometres indiameter. In this process, known as the "Taylor-wire" or "microwire process" or "Taylor-Ulitovski process", the metal to be produced in microwire form is held in a glass tube, typically a borosilicatecomposition, which is closed at one end. This end of the tube is then heated in order to soften the glass to a temperature at which the metal part is in liquid state and the glass can be drawn down to produce a fine glass capillary containing a metal core.

Glass-coated microwires successfully produced by this method include copper, silver, gold, iron, platinum, and various alloy compositions. It has even proved possible to produce amorphous metal ("glassy metal") cores because the cooling rate achievable by this process can be of the order of 1,000,000 kelvins per second. Applications for microwire include miniature electrical components based on copper-cored microwire.

Item Code : TCW-006

Glass-coating is a process invented in 1924 by G. F. Taylor and converted into production machine by Ulitovski for producing fine glass-coated metal filaments only a few micrometres indiameter. In this process, known as the "Taylor-wire" or "microwire process" or "Taylor-Ulitovski process", the metal to be produced in microwire form is held in a glass tube, typically a borosilicatecomposition, which is closed at one end. This end of the tube is then heated in order to soften the glass to a temperature at which the metal part is in liquid state and the glass can be drawn down to produce a fine glass capillary containing a metal core.

Glass-coated microwires successfully produced by this method include copper, silver, gold, iron, platinum, and various alloy compositions. It has even proved possible to produce amorphous metal ("glassy metal") cores because the cooling rate achievable by this process can be of the order of 1,000,000 kelvins per second. Applications for microwire include miniature electrical components based on copper-cored microwire.

Item Code : TCW-007

Glass-coating is a process invented in 1924 by G. F. Taylor and converted into production machine by Ulitovski for producing fine glass-coated metal filaments only a few micrometres indiameter. In this process, known as the "Taylor-wire" or "microwire process" or "Taylor-Ulitovski process", the metal to be produced in microwire form is held in a glass tube, typically a borosilicatecomposition, which is closed at one end. This end of the tube is then heated in order to soften the glass to a temperature at which the metal part is in liquid state and the glass can be drawn down to produce a fine glass capillary containing a metal core.

Glass-coated microwires successfully produced by this method include copper, silver, gold, iron, platinum, and various alloy compositions. It has even proved possible to produce amorphous metal ("glassy metal") cores because the cooling rate achievable by this process can be of the order of 1,000,000 kelvins per second. Applications for microwire include miniature electrical components based on copper-cored microwire.

Item Code : TCW-008

Glass-coating is a process invented in 1924 by G. F. Taylor and converted into production machine by Ulitovski for producing fine glass-coated metal filaments only a few micrometres indiameter. In this process, known as the "Taylor-wire" or "microwire process" or "Taylor-Ulitovski process", the metal to be produced in microwire form is held in a glass tube, typically a borosilicatecomposition, which is closed at one end. This end of the tube is then heated in order to soften the glass to a temperature at which the metal part is in liquid state and the glass can be drawn down to produce a fine glass capillary containing a metal core.

Glass-coated microwires successfully produced by this method include copper, silver, gold, iron, platinum, and various alloy compositions. It has even proved possible to produce amorphous metal ("glassy metal") cores because the cooling rate achievable by this process can be of the order of 1,000,000 kelvins per second. Applications for microwire include miniature electrical components based on copper-cored microwire.

Glass Coated Wire

The range of diameter options available at our store varies from .025 to .25 meter. However, if there is any specific requirement from the customer’s side than a glass coated wire can be customized as per their needs and requirements. To create these wires coated with glass bears a unique combination of glass to metal.

We offer a one stop solution to all your glass coated wire needs with full proof quality assurance. So, if the search of a right place to buy glass coated wires, just visit our website and see the range of our products. There you can not only select your preferred product but can also place your orders very easily. Searching for products is very easy at this portal as it has been designed in a complete user friendly manner. In past few years, we have emerged as one of the most trusted brands in this domain, which has helped us a lot in further improving the quality of and reliability of the products.