Bare copper wires have been in use for the last one hundred and fifty years. The whole idea of industrialization and rapid communication was built around the humble strands of copper wires. Today, with digitalization of the industrial segment, copper wires have not lost their importance at all. From Aerospace industry to underwater missions, every electrical and electro-mechanical circuit uses copper wires. Metallurgical and mechanical advancement has ensured that the effects of harsh climate, corrosive medium and human actions don’t affect the performance of the gadgets fit with copper wires.

Common forms of copper wires available in the commercial space today are:

Bare copper wires

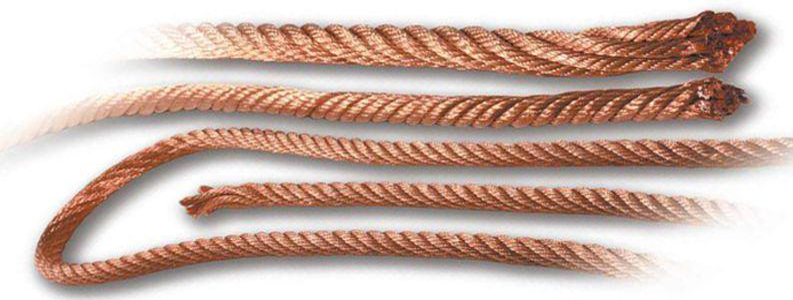

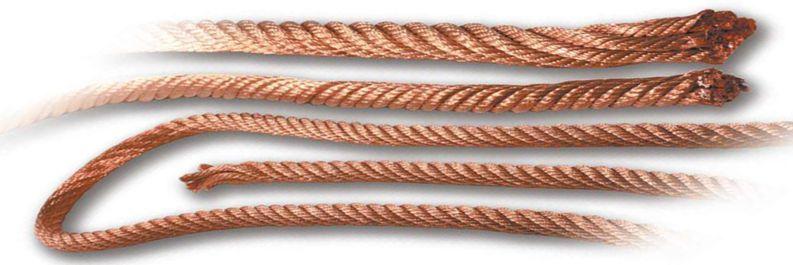

Bunched copper wires

Braided copper wires

Stranded copper wires

Bare and stranded copper wires used in the automobiles are distinguished from the electrical wires by virtue of their resistance to corrosion and extensive elasticity. Most of these wires are tinned bare copper wires and are used in ancillary units like lighting system, air conditioning unit, automatic electronic transmission, braking systems, and even seat recoiling mechanism.

The common varieties of copper wires used for general applications in automobile are as follows.

GPT – They are common circuit wires.

TWP – These wires are lighter and have a reduced diameter as compared to the GPT. They find their use in applications where space is a constraint and require thinner wire.

HDT – Highly shielded and offer greater protection than GPT wires.

SXL – Best wires for optimal application in automobiles and marine engineering, SXL wires are extensively used in high temperature regions. It can easily withstand a temperature of up to 125 degrees Celsius

GXL – They are solid application wires in places demanding thinner wire and resistance to higher temperatures and greasy environment.They are used in underwater probes, miniature airplanes, unmanned aerial units and bikes. Submarines and nuclear-arms are also loaded with GXL wires considering their resistance to extreme weather conditions and temperature fluctuations.

TXL – In addition to high heat resistance and a thin diameter, TXL copper wire is engineered with lightness and durability in mind.

Availability of bare copper wires engineered as trailer and conductor cables, along with SGT, SGX and STX wire types in batteries make the whole segment of automobile wires a fascinating segment.

All these forms are differentiated on the basis of insulation material and the purity of copper used. With amalgamation of copper, it is understood that some impurity in the form of compatible metals would be added into the structure. It is called alloying of copper. Tin, zinc and nickel are commonly added to bare copper to strengthen its physical and chemical properties.

Physical properties like durability, malleability and ductility are significantly enhanced with alloying. Insulation is another process done over bare copper wires. Insulated wires are used in greasy industrialized operations where there is a constant risk of short-circuiting due to high temperatures, breaking of wires and corrosion.

Apart from mechanical strength, insulation also ensures that the bare copper wire carrying electricity remains out of contact.