Glass Wire

In Glass wire drawn copper wire is used which is made by doing stranding and then conductor is made which is basically made of Bare Copper or Tin Copper and is having Glass Tape laping on the same after that Fiber Glass Thread Braided is done on the same and after that Platting of Warness is also done which is used in Electric Motor, Alignment Heater, Submersible Motor, Transformer and High Temperature used Instrument.

Item Code : TCW-001

Glass-coating is a process invented in 1924 by G. F. Taylor and converted into production machine by Ulitovski for producing fine glass-coated metal filaments only a few micrometres indiameter. In this process, known as the "Taylor-wire" or "microwire process" or "Taylor-Ulitovski process", the metal to be produced in microwire form is held in a glass tube, typically a borosilicatecomposition, which is closed at one end. This end of the tube is then heated in order to soften the glass to a temperature at which the metal part is in liquid state and the glass can be drawn down to produce a fine glass capillary containing a metal core.

Glass-coated microwires successfully produced by this method include copper, silver, gold, iron, platinum, and various alloy compositions. It has even proved possible to produce amorphous metal ("glassy metal") cores because the cooling rate achievable by this process can be of the order of 1,000,000 kelvins per second. Applications for microwire include miniature electrical components based on copper-cored microwire.

Item Code : TCW-002

Glass-coating is a process invented in 1924 by G. F. Taylor and converted into production machine by Ulitovski for producing fine glass-coated metal filaments only a few micrometres indiameter. In this process, known as the "Taylor-wire" or "microwire process" or "Taylor-Ulitovski process", the metal to be produced in microwire form is held in a glass tube, typically a borosilicatecomposition, which is closed at one end. This end of the tube is then heated in order to soften the glass to a temperature at which the metal part is in liquid state and the glass can be drawn down to produce a fine glass capillary containing a metal core.

Glass-coated microwires successfully produced by this method include copper, silver, gold, iron, platinum, and various alloy compositions. It has even proved possible to produce amorphous metal ("glassy metal") cores because the cooling rate achievable by this process can be of the order of 1,000,000 kelvins per second. Applications for microwire include miniature electrical components based on copper-cored microwire.

Item Code : TCW-003

Glass-coating is a process invented in 1924 by G. F. Taylor and converted into production machine by Ulitovski for producing fine glass-coated metal filaments only a few micrometres indiameter. In this process, known as the "Taylor-wire" or "microwire process" or "Taylor-Ulitovski process", the metal to be produced in microwire form is held in a glass tube, typically a borosilicatecomposition, which is closed at one end. This end of the tube is then heated in order to soften the glass to a temperature at which the metal part is in liquid state and the glass can be drawn down to produce a fine glass capillary containing a metal core.

Glass-coated microwires successfully produced by this method include copper, silver, gold, iron, platinum, and various alloy compositions. It has even proved possible to produce amorphous metal ("glassy metal") cores because the cooling rate achievable by this process can be of the order of 1,000,000 kelvins per second. Applications for microwire include miniature electrical components based on copper-cored microwire.

Item Code : TCW-004

Glass-coating is a process invented in 1924 by G. F. Taylor and converted into production machine by Ulitovski for producing fine glass-coated metal filaments only a few micrometres indiameter. In this process, known as the "Taylor-wire" or "microwire process" or "Taylor-Ulitovski process", the metal to be produced in microwire form is held in a glass tube, typically a borosilicatecomposition, which is closed at one end. This end of the tube is then heated in order to soften the glass to a temperature at which the metal part is in liquid state and the glass can be drawn down to produce a fine glass capillary containing a metal core.

Glass-coated microwires successfully produced by this method include copper, silver, gold, iron, platinum, and various alloy compositions. It has even proved possible to produce amorphous metal ("glassy metal") cores because the cooling rate achievable by this process can be of the order of 1,000,000 kelvins per second. Applications for microwire include miniature electrical components based on copper-cored microwire.

Glass Wire

Due to its excellent electrical conductivity, copper is the most preferred metal for several crucial industries such as electrical, Manufacturing and others. Copper wires, tin copper wire, braided copper wire etc are heavily preferred by manufacturers and producers of electrical appliances.

Copper wire drawn from glasses, which are also known as glass wire, is now the most preferred conductor for several electric devices such as electric heater, electric motor, submersible pump and other high temperature devices. Glass wires are formed by stranding glass on the copper wires.

Glass coated wire comprises of a unique glass to metal combination, which has a hermetic seal. The physical properties of a glass wire are as follows: extremely smooth and non-porous, which is one hundred percent organic in nature. Basically, glass wire is used to protect the copper wire from oxidation, insulation and other hardcore chemical and atmospheric changes, thus increasing its age and productivity. Normally, the diameter of a glass wire ranges from 0.025 to 0.25 meter, but it can be customized as per specific requirements as well.

Glass wires are extensively used in the following industries: instrumentation, oceanographic, chemical, automotives, aerospace, military, robotic science, high grade electronics devices, electrical industry, bio-medical industry and many more. Additionally, these wires are also used by artists and sculptures to create amazing creations.

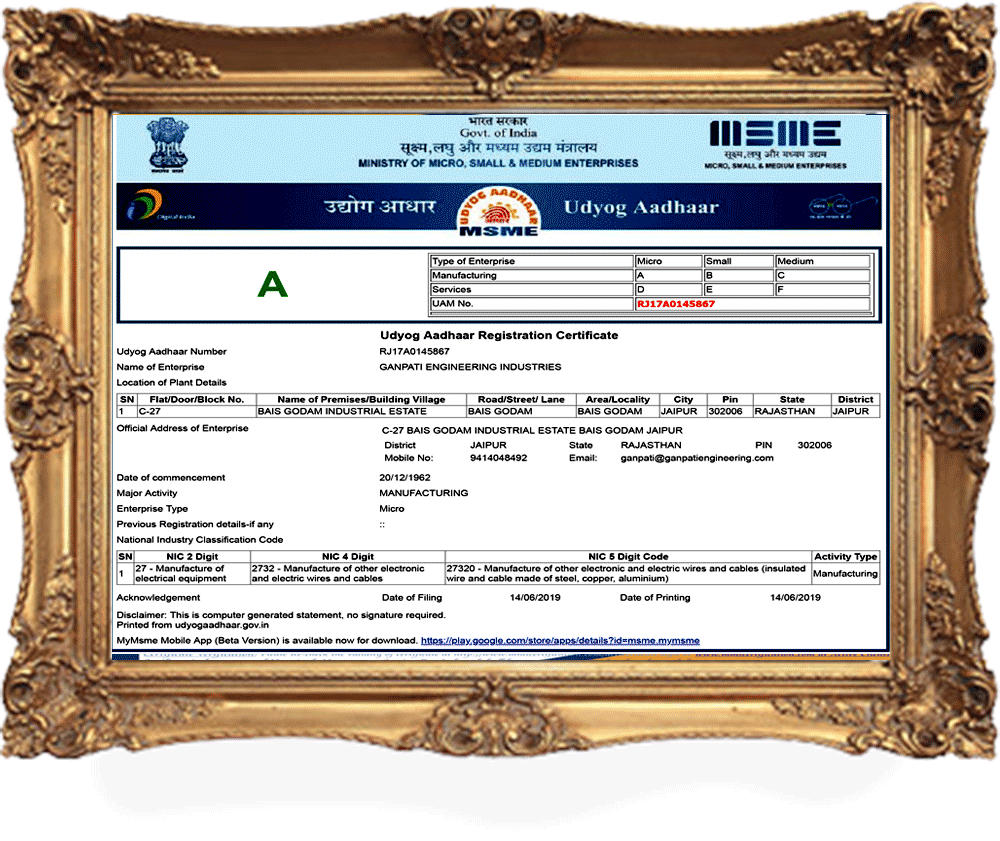

If you are searching for quality glass wires, then your search ends right here. With over 30 years of extensive experience in this industry, Ganpati Engineering is the brand which is trusted and recommended by all.

Ganpati Engineering provides high quality glass wires at reasonable price range. Besides Glass Wires, you can find world class copper wire, tin copper wire, braided copper wire and other products at our website. For more information, all you need to do is send us a mail at ganpati@ganpatiengineering.com.