Copper is one amongst the most important metals, used by us. This metal gains upper hand in context of home wiring purpose. In fact, wires drawn out of this metal are used in wide range of applications right from electronic device to automotives, from motor to scientific instruments, etc. You may have read a lot about properties of this red-orange metal, its uses, its features, etc. However, have you ever wondered about its recycling? Entire recycling process of this metal is quite extremely interesting.

Recycling process

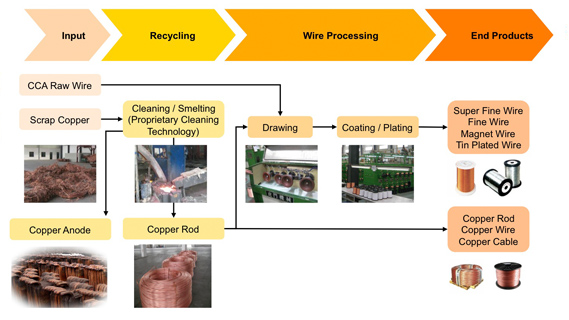

Recycling process of copper wire begins with insulation removal. Removing insulation is extremely crucial before commencing with the process of recycling. A mechanical process removes insulation through cutting it and stripping the same from a copper wire. There also exist another way to remove insulation in the form of using a standard incinerator. Use of incinerator results in destruction of contamination that is being found within insulation. On the contrary, use of low-temperature burning technique results in release of containments into environment.

Negative impacts of using low-temperature burning process

Environment Ministry and recycling industry aim to ensure secure workplaces and implementations of ethical business practices that lay utmost emphasis on public safety and improving environmental stewardship. Recycling industries of few specific regions have given unanimous consent towards curtailing use of copper wire, processed via low-temperature burning. During the process of low-temperature burning, harmful toxins in the form of lead, dioxins, polycyclic hydrocarbons, furans, etc releases into water, soil, air and impact health of humans and lead to adverse impact on environment. When humans are exposed to such contaminants, they tend to experience serious health ailments like irritation in lung, cancer, cardiac problems, etc.

Benefits of recycling copper wire

This metal exists in abundance in earth’s crust and hence you may question the relevancy of recycling. Well, recycling does not merely hold importance in the context of scarce materials. It also holds relevance in context of materials existing in abundance, due to various reasons. Primary benefit of this process is that, less amount of fresh raw material is required for manufacturing copper wire. Another major benefit is related to environment. As less amount of copper is dumped on land, it does not lead to much negative impact on nature. Worldwide metal recycling companies are able to make profit out of recycling of copper. They purchase old wires of copper for nominal prices and thereafter further send it for smelting and re-refining. In fact, marketing of old copper wires take place at large scale.

Saving resources and energy play determining role in protecting environment. It could be possible that in coming time, governments of most of the nations may make it mandatory to save energy. For the same purpose, they may provide some handsome tax exemptions to green industry. To put it into a nutshell, metal recycling process not merely results in energy conservation, but recycled metal also enjoy extensive application related to industrial production. Most popular example is none other than copper cycling itself, wherein most of the copper products that include copper roofing, etc, are comprised of round about 75% copper morsel.